| IR Control / Configuration of 16F88 Controller Because

of a limited number of available pins on the 16F88 an infrared TV

remote control is being used to change settings on the controller.

The IR signal is received by the PNA4602M. It is made to react

only to IR signals that are modulated at 38 KHz, the frequency used

by a typical TV remote control unit.

These signals are decoded in the 16F88 and are used to set

variables, accelerate / decelerate engines and to initiate operation

of the controller.

|

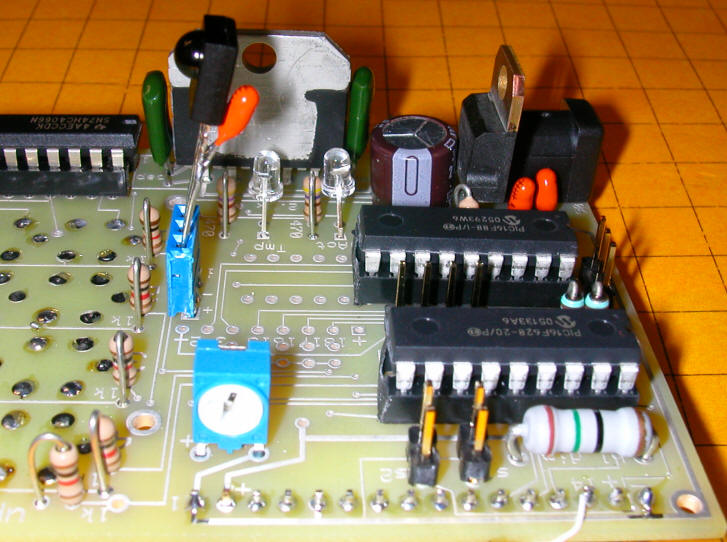

| Circuit Board Photos This is a view of the MiniDCC LCD

(front) and the PIC Controller LCD (back) and the 4 x 4 keypad

(left)

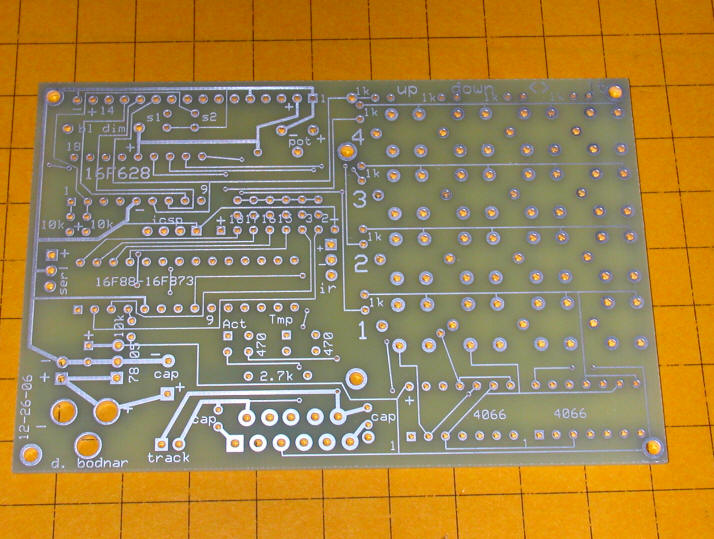

Here is the bare board, component side.

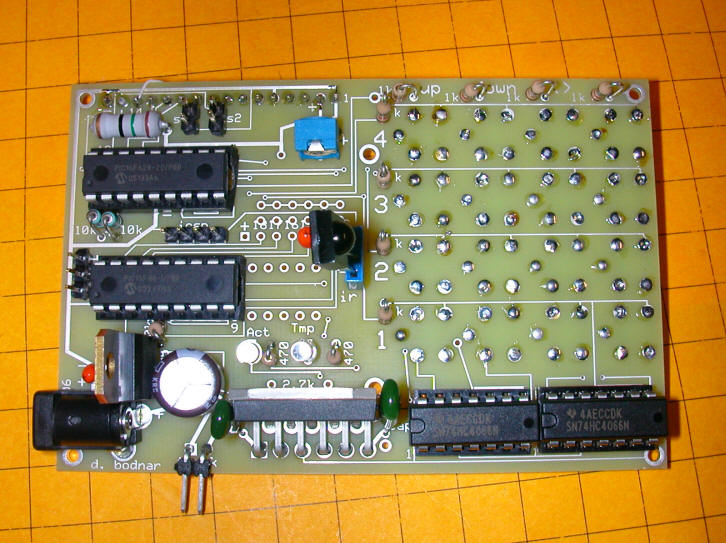

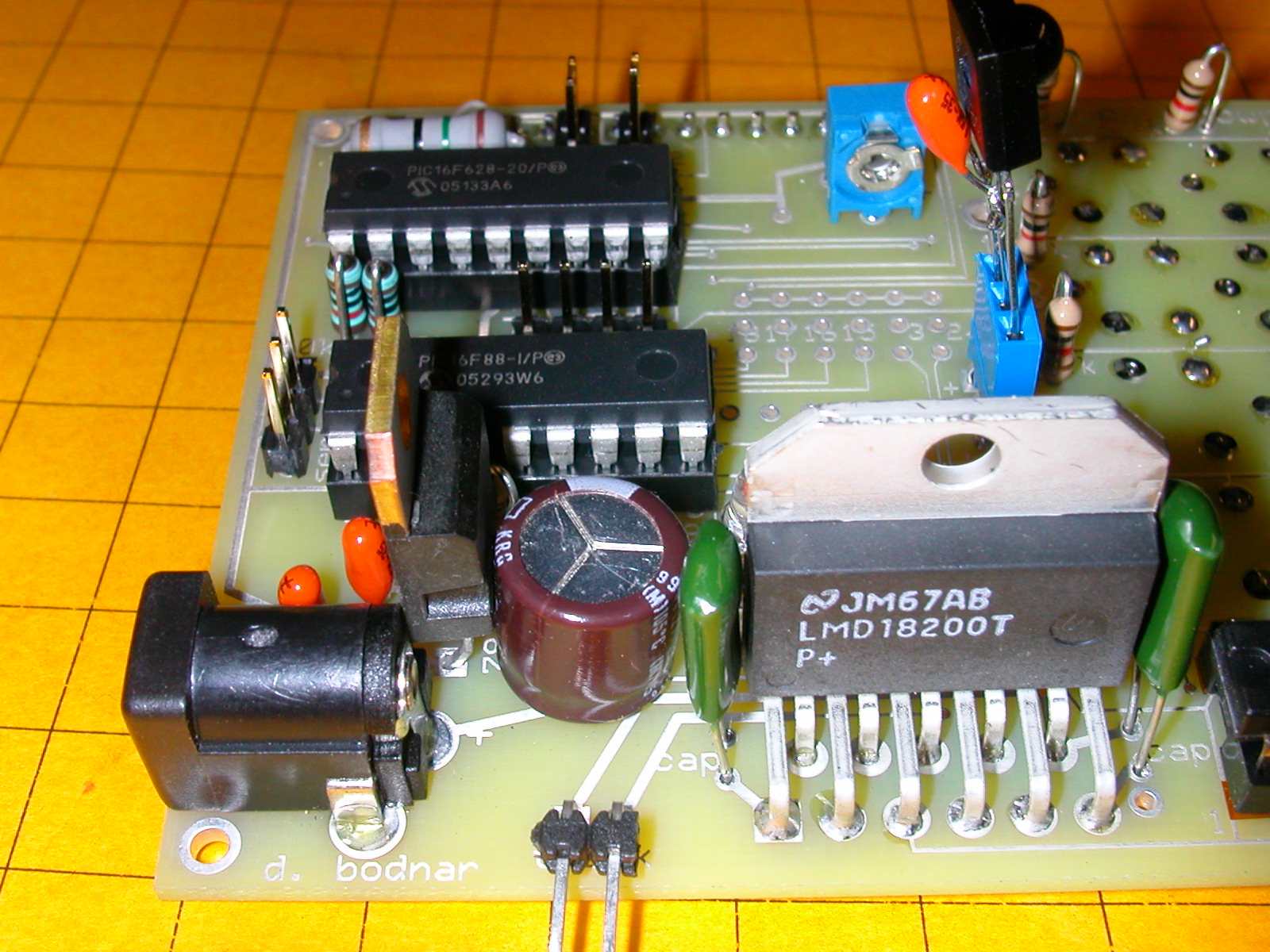

This is an overhead view of the component side with most

components mounted. The MiniDCC PIC is upper left, the PIC

Control chip is just below it, the IR sensor is in the center, the

18200 is bottom center and the two 4066's are bottom right - the

pushbuttons for the keypad are on the other side.

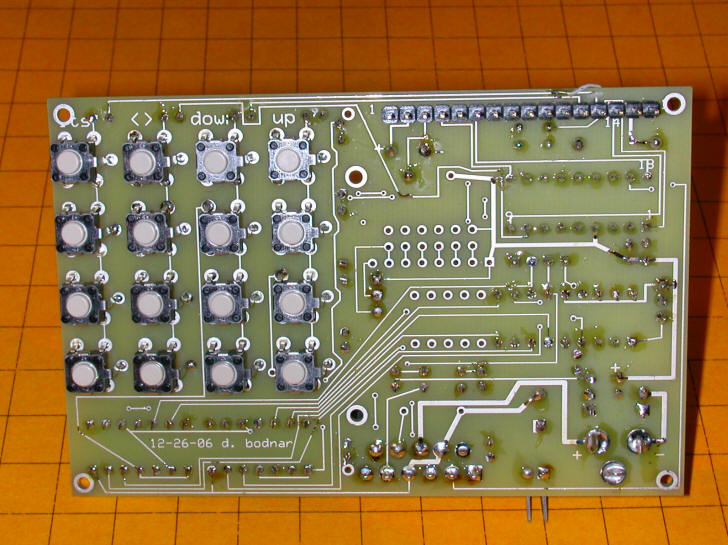

Here is a full view of the keypad side of the board. The

MiniDCC LCD plugs into the header in the upper right.

This is a close-up view of the component side.

A close-up of the 18200 and power supply section.

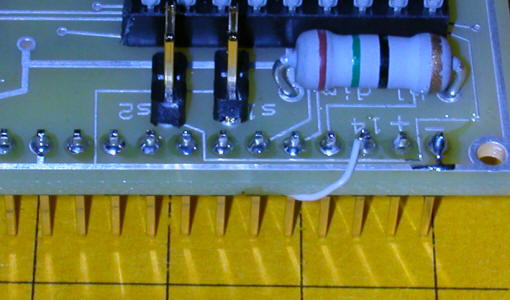

Only one piece of rework was necessary. I miswired the

connection between pin 14 and the headlight section of the keypad

matrix. The fix is in the two photos below. One error on

a board with all of these components is not too bad!

|

| Test Code (PicBasic Pro)

Include "modedefs.bas"

cmcon=7 'allows you to use pins as digital rather than analog

ansel=0 'allows you to use pins as digital rather than analog

@ DEVICE PIC16F88, INTRC_OSC_NOCLKOUT, WDT_OFF, LVP_OFF, PWRT_ON,

PROTECT_ON, BOD_ON

OSCCON = %01100111 'MUST BE USED to set clock speed %01100111 =$67 =

4mhz

clear

Serial_out var PORTA.2

Ser_Speed con 188

rw0 var portb.0

rw1 var portb.1

rw2 var portb.2

rw3 var portb.2

cl10 var portb.4 ' 10

cl11 var portb.5 ' 11

cl00 var portb.6 ' 12

cl01 var portb.7 ' 13

cl30 var portb.0 ' 6

cl31 var portb.1 ' 7

cl20 var portb.2 ' 8

cl21 var portb.3 ' 9

sensor1 var porta.6 '15

sensor2 var porta.7 '16

sensor3 var porta.0 '17

sensor4 var porta.1 '18

IRin var porta.3

led2 var porta.7 'red LED

led var porta.4 'white LED 'pin 3

temp var word

temp2 var word

temp3 var byte

temp4 var byte

temp5 var byte

temp6 var word

temp7 var word

tempbyte var byte

x var byte

xx var byte

Delay var byte

Delay2 var byte

Vwhole var word

Vdecimal var word

Vwhole=2

Vdecimal=0

zero con 136

one con 128

two con 129

three con 130

four con 131

five con 132

six con 133

seven con 134

eight con 135

nine con 136

channelUP con 144

channelDOWN con 145

volumeUP con 146

volumeDOWN con 147

OK con 148

Menu con 224

ENTER con 139

digit var byte

SpeedStep var word

TempWord var word

TempWord2 var word

value var byte

temp0 var byte

temp1 var word

Train var byte(10)

xxx var byte

trisa.2=0

delay = 15 'was 35

delay2=12

trisb=0 'all of port b to output to drive keyboard on miniDCC

trisa.3=1

trisa.7=0

p_len var byte

steps VAR WORD

trisa = %11001111

Command Var Byte

IRpulse_length var word(13)

'clear

train(1)=0 'cl00

train(2)=2 'cl10

train(3)=4 'cl20

train(4)=6 'cl30

Train(5)=1 'cl01

Train(6)=3 'cl11

Train(7)=5 'cl21

Train(8)=7 'cl31

speedstep=5

'next line toggles all 4066's to initiate them - NEED IT!

for xx=1 to 8:high train(xx):pause 10:low train(xx):pause 10:next

'pause 200

again:

serout2 serial_out, Ser_Speed,["?f?c0"]:pause 200:serout

serial_out,Ser_Speed,["?f?c0"]:pause 200 '?c0 turns cursor off

serout2 serial_out, Ser_Speed,["?B40"]:pause 200 'set brightness of

LCD

serout2 serial_out, Ser_Speed,["MiniDCC Driver_test?nd. bodnar

12-2006?nVersion ",#vwhole,".",#Vdecimal]

pause 200

start:

gosub getir:

if command >=128 and command <=137 and command <> 136 and command <>

134 then

xxx=command-127

if xxx=6 then xxx=7

if xxx=5 then xxx=6

if xxx=4 then xxx=5

if xxx=8 then xxx=4

if xxx=10 then xxx=8

Serout2 serial_out, Ser_Speed,["?y0?x00Cmd= ",#xxx," ",#train(xxx)]

gosub TrainUp:command=0

endif

if command=OK then gosub All_Stop:command=0

if command = enter then goto GetRevSettings

goto start:

TrainUP:

for temp=1 to speedstep :high Train(xxx):pause delay:low

Train(xxx):pause delay:next temp

return

All_Stop:

for temp=1 to 35

for temp2=5 to 8

high train(temp2):pause delay:low train(temp2):pause delay

next temp2

next temp

return

GetIR:

low led

p_len=100

temp4=temp4+1

Serout2 serial_out, Ser_Speed,["?y3?x00@ IR ",#temp4," "]

Getstartbits:

Pulsin IRin ,0,IRpulse_length(0)

if IRpulse_length(0) < 200 then 'was 200 for 4 mhz clock

return

Endif

toggle led

for xx=1 to 12

pulsin IRin,0,IRpulse_length(xx)

next xx

displaybits:

if IRpulse_length(1) < p_len then 'was 100 for 4 mhz clock

Command.bit0 = 0

Else

Command.bit0 = 1

endif

if IRpulse_length(2) < p_len then

Command.bit1 = 0

Else

Command.bit1 = 1

endif

if IRpulse_length(3) < p_len then

Command.bit2 = 0

Else

Command.bit2 = 1

endif

if IRpulse_length(4) < p_len then

Command.bit3 = 0

Else

Command.bit3 = 1

endif

if IRpulse_length(5) < p_len then

Command.bit4 = 0

Else

Command.bit4 = 1

endif

if IRpulse_length(6) < p_len then

Command.bit5 = 0

Else

Command.bit5 = 1

endif

if IRpulse_length(7) < p_len then

Command.bit6 = 0

Else

Command.bit6 = 1

endif

if IRpulse_length(8) < p_len then

Command.bit7 = 0

Else

Command.bit7 = 1

Endif

If Command.bit7 = 0 then 'Bit 7 is one of the device bits

Command = Command + 1

Endif

If Command = 10 then

Command = 0

Endif

serout2 serial_out, Ser_Speed,["?y3?x10CMD= ",#command]

return

GetRevSettings:

digit=2

speedstep=0

high LED:pause 500:low LED

GetRevSettings0:

gosub getir

if command=0 then GetRevSettings0

if command > 137 or command < 128 and command <>139 and command <> 0

then

goto start: 'abort on non number 0-9

endif

if command=139 then GetRevSettings0

Value=command-127

if Value = 10 then value=0

if value=0 then high LED:pause 250:low LED

for tempbyte=1 to value:High LED:pause 100:low LED:pause 100:next

tempbyte

speedstep=speedstep*10+Value

digit=digit-1

pause 100:command=0

if digit=0 then

temp0= speedstep / 256

write 0, temp0

temp1 = temp0*256

temp2= speedstep-temp1

write 1, temp2

'gosub test4:

goto start:

endif

goto GetRevSettings0 |