|

Introduction A few years ago I wrote an article,

A Simple Constant Brightness LED,

that described a circuit that could be used to illuminate an LED to

full brightness over a range of voltages. Since then technology has

continued to advance. I recently came upon a new solid state

device that takes much of the guess work and computation out of the

equation when we use LEDs. 1. LEDs require a minimum voltage to

create light. This voltage can vary with LED color and generally ranges

from 2 - 3 volts. This is called the LED's "forward voltage".

Note that this is a minimum. Higher voltages can be used so long

as one adheres to rule #2.

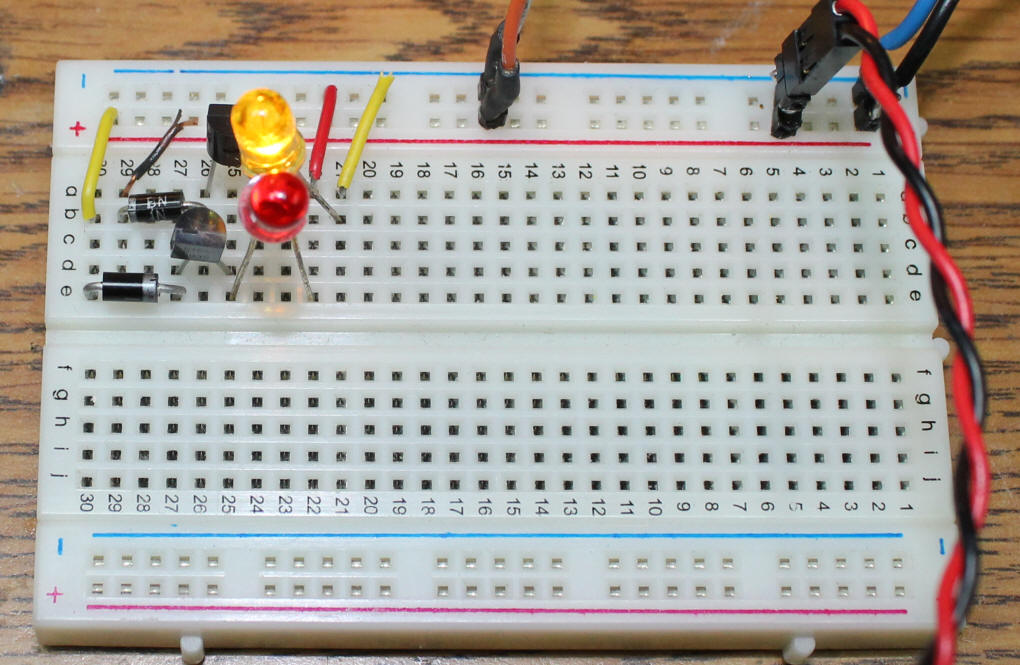

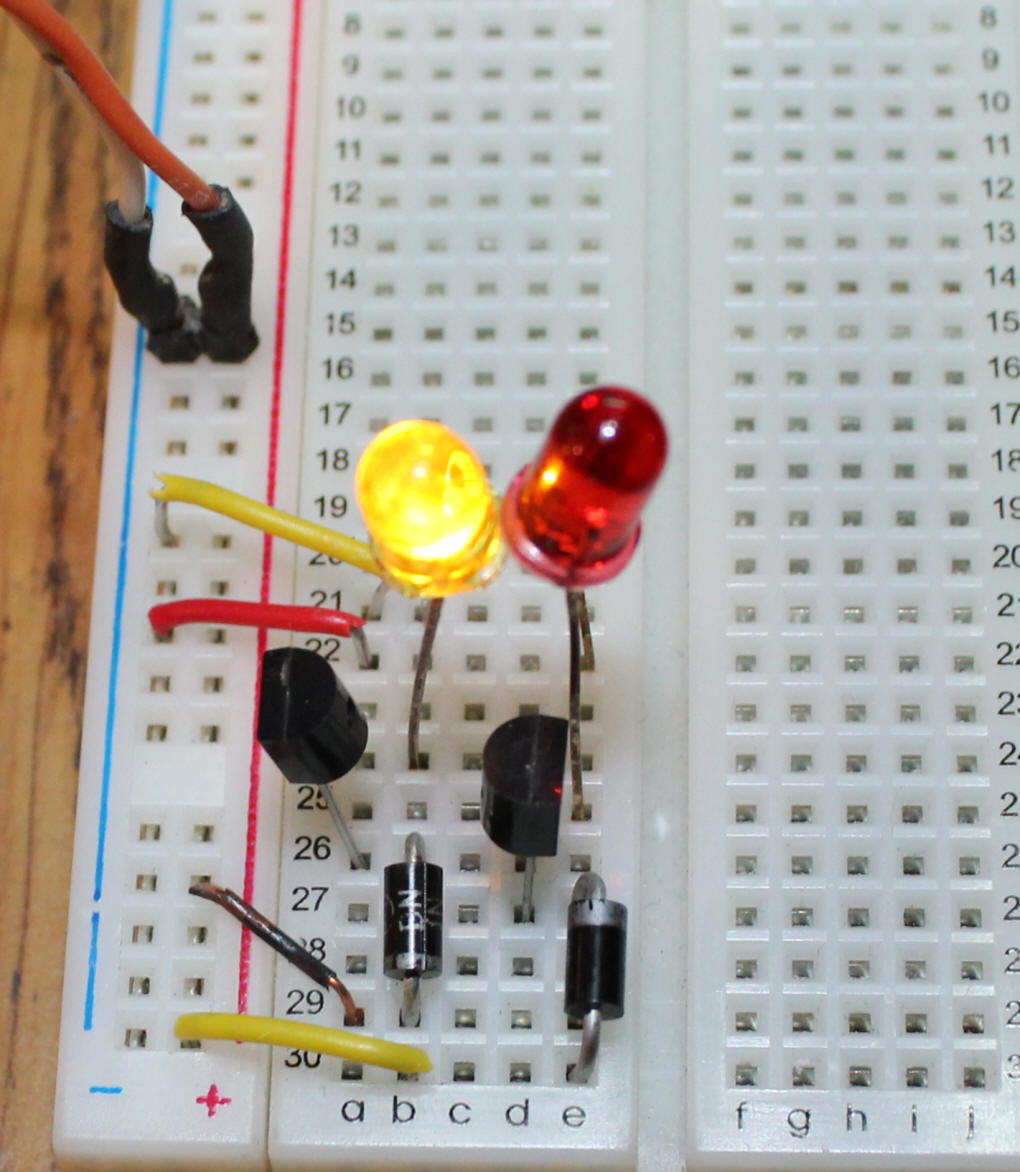

Limiting Current The most common way to limit the current that is allowed to flow through an LED is to place a resistor in series with the LED and its power source. A number of methods of determining the value of this resistor are explored in the LED article referenced above. Typical values range from 100 ohms to 1000 ohms depending on the LED and the voltage that is being used. This is one of the problems with limiting current with resistors, the higher the voltage the higher the resistance must be. This photo shows a very simple LED circuit composed of an LED, a 470 ohm resistor and a common 9 volt battery. Note that the resistor is connected to the positive terminal on the battery and to the anode on the LED. Even though it makes no difference which lead of the LED you connect to the resistor I have gotten into the habit of always putting the resistor on the anode side of the LED. That way I can tell at a glance which lead goes to positive and which goes to negative.

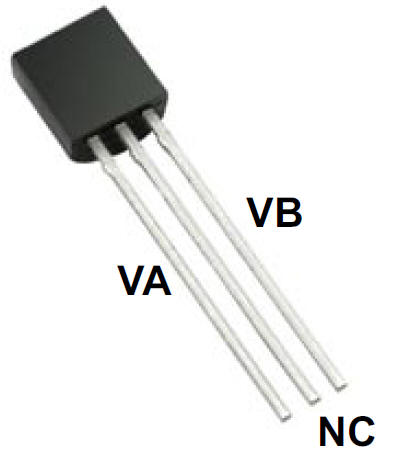

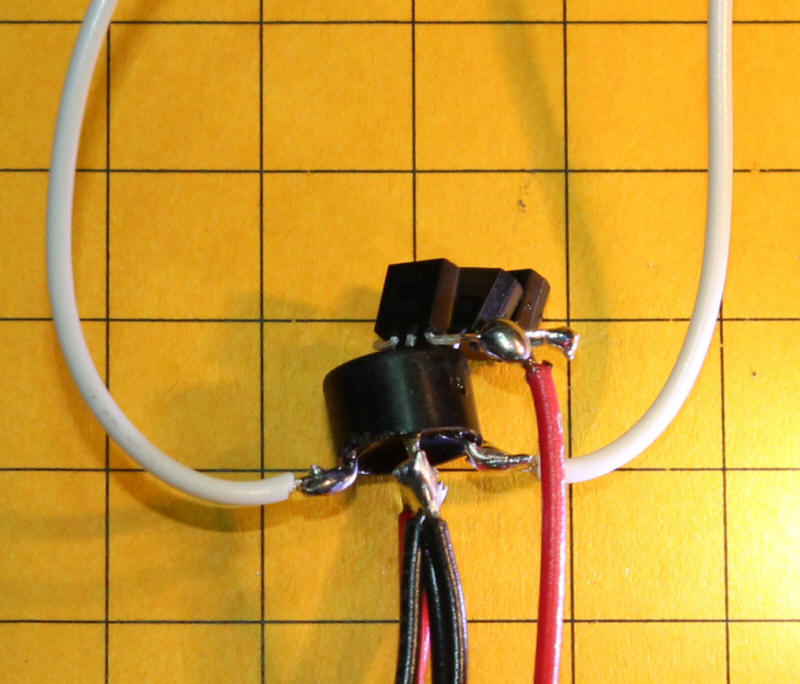

A Better Solution LEDs have become so common in our homes, consumer electronics and automobiles that it is not surprising that an integrated circuit has been developed that is aimed specifically at driving LEDs. This device is the CL2N3-G LED Driver from Supertex. It is inexpensive, even in small quantities, and is configured to deliver a constant current of 20 ma to an LED. The CL2N3-G can be ordered from Mouser Electronics for about $0.44. There is also a similar IC that delivers 25 ma, the CL25N3-G. The CL2N3 couldn't be easier to use. Just insert it in series with the DC power source and the LED. The TO-92 package has three pins but only the outside two are used. The center pin can be cut off. The positive voltage goes to pin VA and pin VB goes to the anode of the LED. Remember, the center pin, labeled NC, is not connected.

Here is a photo of the same circuit. Notice that the center lead of the LED driver has been cut off.

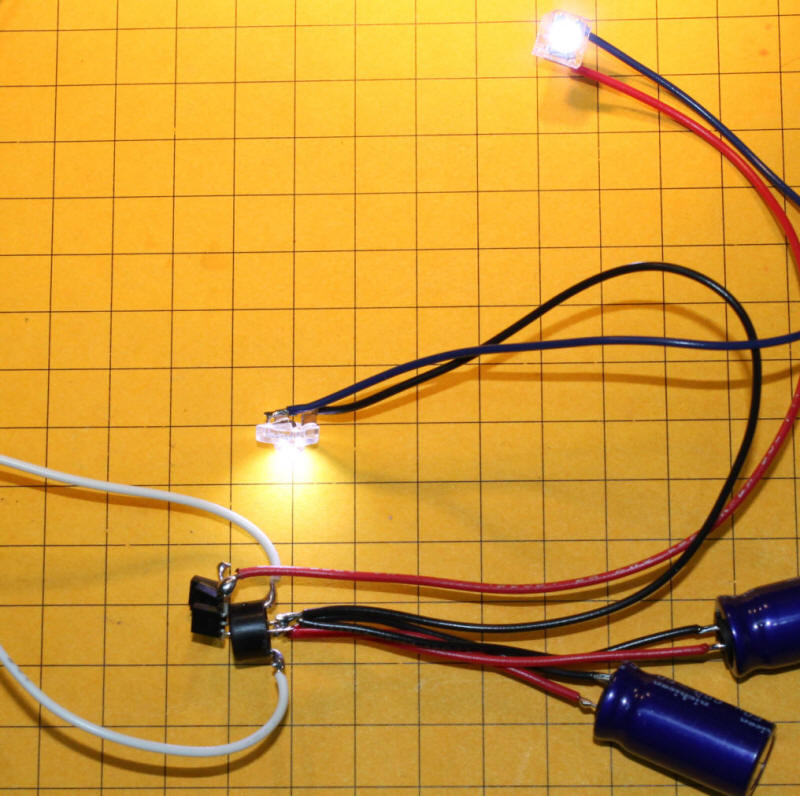

Here you can see four LEDs wired in series along with a single CL2N3. The circuit is powered by a bench power supply that is supplying 17.8 volts, shown on the bottom display. The top display shows that the circuit is drawing 0.02 amps or 20 ma, just as we would expect.

The next three photos show a 1/2 watt LED connected to 17.8 volts. The first photo shows this circuit with a single CL2N3. The meter tells us that 0.02 amps is being supplied to the LED. Here a second CL2N3 has been added to the circuit. It is wired in parallel with the first LED driver. The meter shows that 0.04 amps is being supplied as we would expect. Although it is difficult to see in the photo the LED is also considerably brighter. The last photo in this series shows three CL2N3's in parallel and 0.06 amps going to the LED allowing it to achieve its full brightness.

|